New to antenna systems? See our Complete Guide to Ham Radio Antennas.

Antennas for Australian heat have to handle coastal humidity to inland desert heat. The antenna materials, mounting, and maintenance must resist UV, thermal expansion, and corrosion.

The extreme daytime temperatures and strong sunlight accelerate material aging, which shortens the life of poorly specified hardware. Consequently, choosing the right antenna and protection strategy saves money and ensures reliable on-air performance.

Materials that Survive Heat and Sun

Start with metals that tolerate thermal cycling without rapid corrosion. Stainless steel and marine-grade (6061 or 6063) aluminum alloys remain common choices; however, stainless steel resists corrosion better while aluminum reduces weight. Moreover, use 316 stainless hardware for coastal areas because it resists salt spray.

Choose UV-stabilized plastics and PTFE insulation for insulators and sleeves; otherwise, brittle cracking appears after a few seasons. Finally, where possible, select powdered-coat or anodized finishes because they add UV protection and reduce surface oxidation.

Thermal Expansion

Thermal expansion changes element length in hot conditions, and therefore you must allow mechanical tolerance in telescoping or sectional antennas. For example, aluminum’s linear expansion coefficient is about 23 × 10⁻⁶ per °C.

Coatings, Radomes, and UV Protection

Protective coatings extend service life. Powder coating on aluminum and marine lacquer on stainless parts reduce direct UV attack. Therefore, always specify UV-stable radome materials for exposed active elements and matching boxes.

Use silicone or polyurethane sealants to close joints, but ensure the chosen sealant lists UV and high-temperature ratings; otherwise, the sealant will crack and invite moisture. Finally, for sensitive matching networks and baluns, house them in ventilated, UV-resistant enclosures that keep internal temperatures stable.

Feedline and Connector Choices for High Heat

Coax jackets degrade under UV and heat, and therefore use LMR-style low loss cables with UV-stable polyethylene jackets or double-jacketed marine coax when exposed. In addition, choose connectors with corrosion resistant plating, silver or gold-plated center pins and tin or nickel plating on outer shells.

Use heat-shrink with adhesive liner for weatherproofing, and apply a silicone overcoat on the connector seams to prevent water ingress. Finally, run feedlines in conduit or under eaves to reduce direct sun loading and reduce the temperature swings seen by the cable.

Matching Networks, Baluns, and Thermal Stress

Baluns and matching coils can heat under sun and transmit dissipation, and therefore mount them on heat-dissipating plates and ventilate enclosures. In addition, select capacitors with temperature-stable dielectric (NP0 or C0G) where tuning sensitivity matters. Consequently, your matching remains stable as temperatures shift through the day. Meanwhile, avoid cheap varnished coils that crack; instead use sealed powder-coated forms or epoxy only when rated for UV and thermal cycles.

Mechanical Design: Joints, Clamps, and Fasteners

Design for flex and slip. First, use slotted holes or spring washers to maintain torque as parts expand and contract. Next, specify stainless steel U-bolts with oversized saddles and torque them to a documented setting; then retorque after the first week and again after a month.

Locknuts or Nylock inserts reduce loosening, and thread-locking compounds that are UV-resistant help where disassembly is rare. Finally, avoid mixing aluminum and copper directly; instead isolate dissimilar metals with PTFE washers or specific insulating hardware.

Mounting, Ventilation, and Enclosure Strategies

Place matching boxes and tuners where they get airflow but not direct midday sun. Therefore, mount enclosures on shaded sides of the mast or under a small vented weather hood. In addition, install temperature sensors and a simple low-power fan triggered above a threshold to keep internal electronics within rated limits.

Do not enclose active radiating elements within tight sealed radomes without consideration, trapped heat can raise element temperature, shift resonance, and change SWR in predictable ways.

Salt Spray and Coastal Considerations

Coastal exposure accelerates corrosion, and therefore apply extra protection in maritime zones. Use 316 stainless hardware, marine anodized aluminum, and regular fresh-water rinses after storms. Moreover, inspect connectors quarterly and replace sacrificial washers as needed. In addition, use dielectric grease on exposed contacts to reduce salt crystallization and maintain low resistance.

Electrical Grounding and Lightning Protection

High temperatures often coincide with convective storms, so bolt down a proper lightning path to earth. Therefore, bond antenna structures to a low-impedance earth system with wide copper straps and surge protectors at the entry point. In addition, use gas discharge tubes or hybrid arrestors rated for HF transients, and maintain bonding continuity between tower, shack ground, and AC safety earth.

If a 10 meter aluminum boom experiences a 40 °C temperature rise, calculate expansion step by step: 23 × 10⁻⁶ × 10.00 m × 40 = 23 × 10⁻⁶ × 400 = 9,200 × 10⁻⁶ m = 0.0092 m, which equals 9.2 mm. Thus, roughly a one-centimeter change over a 10-meter element is realistic in extreme heat, and you must secure joints to prevent loosening or fatigue as a result.

Choice of Antenna Types

For exposed rooflines and hot deserts, prefer simple wire dipoles, folded dipoles, and loop antennas that use fewer mechanical joints and lighter hardware. In contrast, heavy multi-section collinear and phased arrays require more attention because connectors and clamps loosen under repeated thermal cycling.

For coastal tropical zones, choose stainless hardware with sacrificial anodes where metal meets saltwater spray. Meanwhile, fiberglass masts and non-conductive supports help avoid heat-sourced galvanic corrosion where dissimilar metals contact.

Examples That Survive Australian Heat

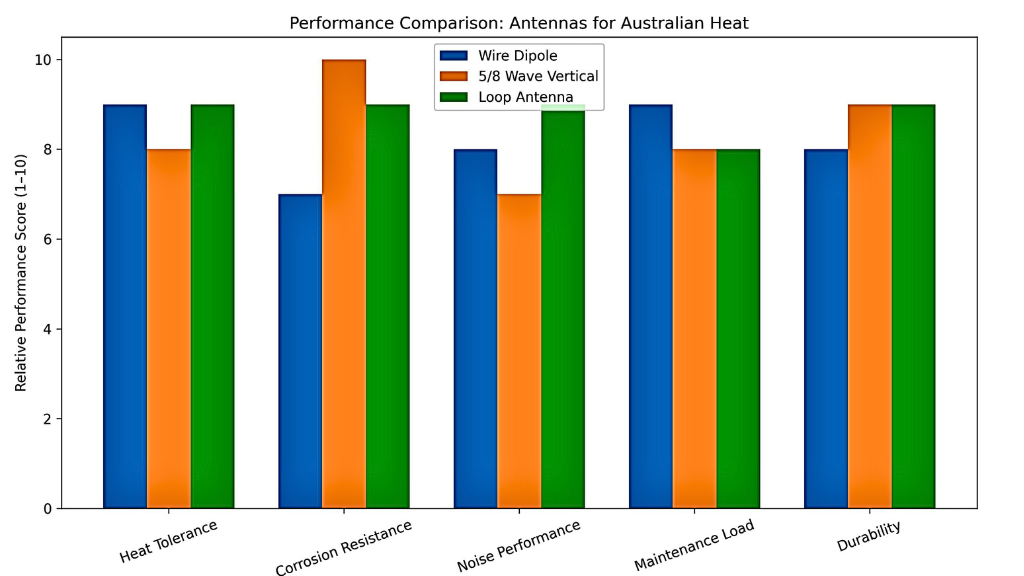

Below are three specific antenna types that perform well in extreme Australian conditions. Each example includes why it works in heat, what materials to use, and what to watch for during installation.

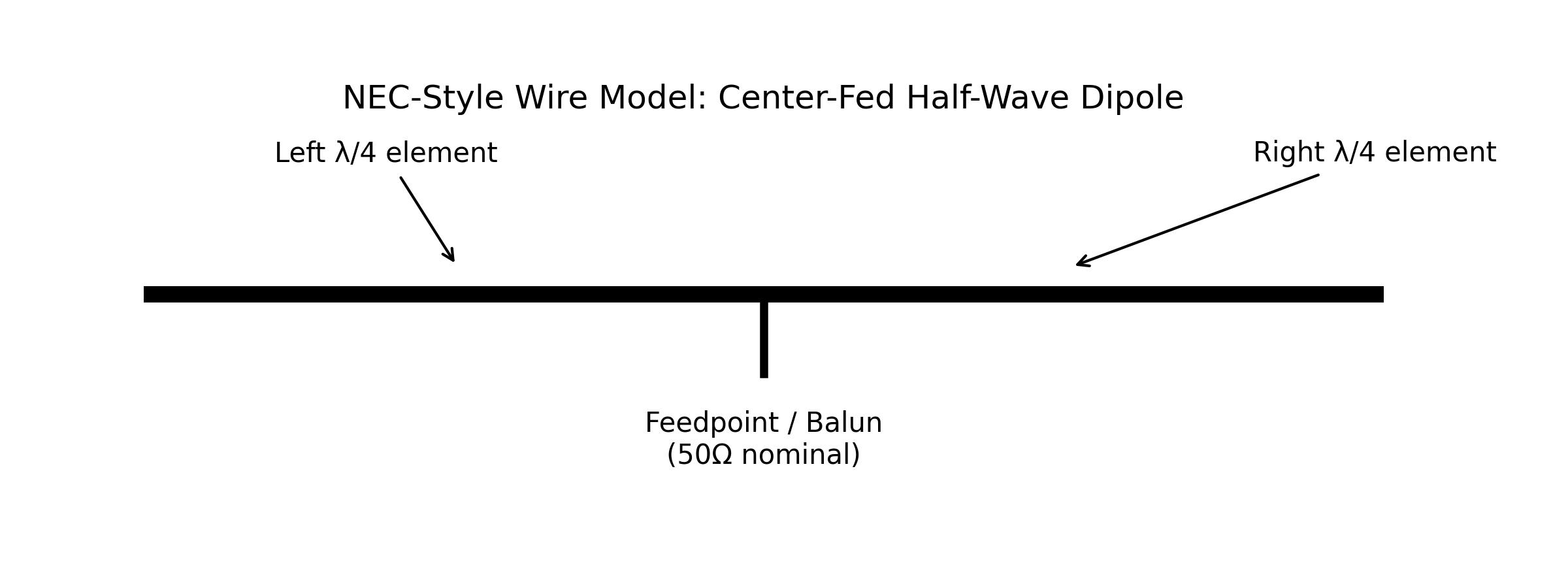

1. Full-Size Wire Dipole for HF

A full-size copper or copper-clad steel wire dipole remains one of the most heat-tolerant antennas you can install. Because it contains no traps, coils, or plastic loading components, it handles thermal cycling with minimal stress points. Moreover, stranded copper wire expands without cracking, which reduces mechanical fatigue over time.

Use UV-stabilized insulators and Dacron or Kevlar support rope, and therefore the antenna will survive harsh sun exposure for years. In addition, keep tension moderate rather than extreme, because wire length increases slightly in high heat. Consequently, you avoid snapping support lines during summer expansion.

Best for:

- Rural properties

- Hot inland regions

- Low-maintenance installations

- Cheap PVC insulation that becomes brittle in UV

- Over-tight tensioning

Avoid:

2. Stainless Steel 5/8-Wave VHF Vertical

A stainless steel 5/8-wave vertical works exceptionally well in high-heat and coastal environments. Because stainless steel resists corrosion and maintains structural strength under thermal stress, it tolerates salt air and strong sun exposure. Moreover, this design uses minimal plastic components, which reduces UV degradation.

Mount it with 316 stainless hardware and include a proper current choke below the feedpoint. Therefore, you maintain pattern integrity and reduce feedline radiation even as temperature changes. In addition, ensure the matching network sits inside a ventilated, UV-resistant enclosure so internal components do not overheat.

Best for:

- Coastal Australia

- High UV environments

- Permanent repeater or simplex installs

Avoid:

- Thin aluminum with untreated hardware in salt air

- Fully sealed matching boxes with no heat relief

3. Aluminum Loop Antenna (Delta or Horizontal Loop)

An aluminum or copper loop antenna performs extremely well in heat because it distributes mechanical stress evenly across its perimeter. Therefore, no single point carries excessive load during thermal expansion. Additionally, loops use fewer mechanical joints than multi-element beams, which reduces loosening under heat cycling.

Choose marine anodized aluminum tubing and isolate dissimilar metals with PTFE washers. Consequently, you prevent galvanic corrosion in humid or coastal climates. Moreover, loops often exhibit low noise reception characteristics, which helps in suburban heat islands where electronic noise increases during peak energy demand.

Best for:

- Suburban rooftops

- High-noise areas

- Long-term fixed installs

Avoid:

- Direct aluminum-to-copper contact without isolation

- Poorly sealed feedpoint enclosures

Why These Three Work in Australian Conditions

Each of these antennas shares critical survival traits:

- Minimal plastic stress points

- UV-resistant materials

- Tolerance for thermal expansion

- Simple mechanical construction

- Easily serviceable components

Because Australian summers combine UV intensity, heat, and sudden storms, simplicity becomes an advantage. Therefore, antennas with fewer traps, fewer sealed plastic housings, and fewer dissimilar metals consistently outlast more complex designs.

Tuning, Thermal Tracking, and Frequency Stability

Expect resonance to shift with thermal load; therefore implement procedures to retune after midday peaks. Use an antenna analyzer to log resonance vs. temperature and then create a small lookup table.

For very precise installations you can compensate with a remote-tuned matching network or an automatic antenna tuner that adjusts as conditions change. Meanwhile, for portable or temporary setups, plan to trim elements after they reach operating temperature to get the final resonance where you need it.

Maintenance Schedule and Inspection Checklist

Heat accelerates wear, therefore inspect high-exposure installations at least twice per year and seasonal sites quarterly. Check fastener torques, reapply grease, check sealant integrity, and test feedline continuity and SWR. In addition, perform a visual inspection after any extreme heatwave or storm event. Document findings and repeat measurements to detect trends rather than single-point anomalies.

Practical Recommendations by Australian Region

In hot, arid interiors: use aluminum elements for weight savings but plan for larger expansion tolerance and keep joints slotted. The tropical north: prefer stainless 316 hardware, UV-stable plastics, and frequent rinsing after storms. In humid coastal east and south: combine marine anodizing, sacrificial paint coats, and twice-yearly inspections. In temperate highland areas: standard RF practices work, but still plan for UV exposure during clear summer days.

Cost vs Longevity Tradeoffs

Buying marine-grade materials increases upfront cost but reduces replacement and outage expenses. Therefore, run a life-cycle calculation and prioritize hardware longevity for permanently installed arrays. Meanwhile, for short-term deployments or contest masts, accept lighter duty parts but inspect them immediately after the event.

Antennas for Australian Heat

First, pick corrosion-resistant materials and UV-stable insulators. Next, design for thermal expansion with slotted joints and lock hardware. Then, provide ventilation or active cooling for sealed matching boxes. After that, route feedlines away from direct sun and waterproof every connector. Finally, schedule a maintenance cadence and record baseline SWR and impedance values for seasonal comparison.

Please consider Donating to help support this channel