Complete Guide to Ham Radio Tools

Complete Guide to Ham Radio Tools, smooth operation depends on far more than transceivers and antennas. Behind every reliable station is a collection of tools that allow operators to build, test, adjust, troubleshoot, and maintain equipment. These tools make installation safer, improve signal performance, and help diagnose problems quickly and accurately.

Whether you are assembling antennas, tuning feedlines, testing power output, or tracking down interference, the right tools transform guesswork into precise control. Understanding what tools do, why they matter, and how to use them correctly is essential for building and maintaining an effective amateur radio station.

This guide explains the most important ham radio tools, how they are used, and how they support station performance and reliability.

Please consider Donating to help support this channel

Why Tools Matter in Amateur Radio

Radio systems depend on proper electrical performance, mechanical stability, and signal efficiency. Small problems such as poor connections, mismatched impedance, or unwanted RF feedback can dramatically reduce station effectiveness.

Tools allow operators to:

- Measure electrical performance

- Verify antenna behavior

- Diagnose signal problems

- Ensure safe installation

- Maintain consistent operation

Without measurement and testing tools, station adjustments rely on guesswork. Accurate tools provide real data, allowing informed decisions that improve communication quality.

Measuring RF Power and Standing Wave Ratio

One of the most important measurements in any station is Standing Wave Ratio, or SWR. This indicates how efficiently power transfers from transmitter to antenna.

An SWR meter measures forward and reflected power. High reflected power indicates mismatch, which can reduce signal strength and stress transmitter components.

Power meters also verify transmitter output. Monitoring power ensures the radio operates within expected limits and helps identify performance changes over time.

These instruments are fundamental for antenna installation, feedline testing, and general station monitoring.

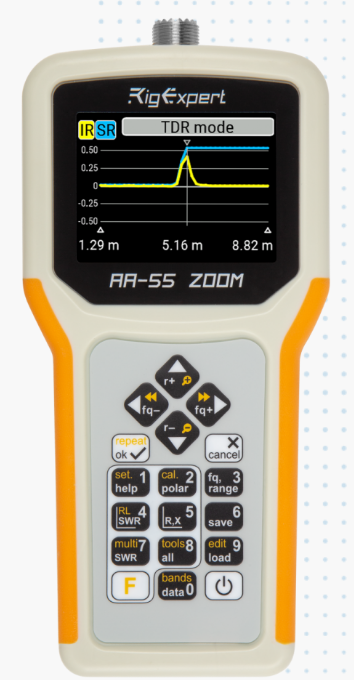

Antenna Analyzers and Impedance Measurement

Antenna analyzers provide detailed information about antenna behavior across frequency ranges. They measure impedance, resonance, and SWR without transmitting full power.

Analyzers help operators:

- Find antenna resonance

- Adjust antenna length

- Diagnose feedline problems

- Evaluate matching networks

- Test antenna systems safely

Advanced analyzers can display complex impedance, reactance, and frequency response curves, allowing precise tuning for optimal performance.

Multimeters for Electrical Testing

A multimeter is one of the most essential general-purpose tools. It measures voltage, current, and resistance, allowing operators to verify power supplies, continuity, and component function.

Common uses include:

- Checking DC power systems

- Testing cable continuity

- Verifying grounding

- Measuring component values

- Troubleshooting equipment faults

Reliable electrical measurements are critical for safe and stable station operation.

Oscilloscopes and Signal Visualization

Oscilloscopes display electrical signals as waveforms. They allow operators to see modulation characteristics, distortion, and timing behavior.

In advanced stations, oscilloscopes help evaluate:

- Audio processing

- Signal modulation

- Power supply ripple

- RF envelope behavior

Visualizing signals provides deeper understanding of how equipment performs under real operating conditions.

Dummy Loads for Safe Testing

A dummy load provides a non-radiating electrical load that absorbs transmitter power. This allows testing and tuning without transmitting signals over the air.

Dummy loads are used for:

- Transmitter adjustment

- Power testing

- Equipment troubleshooting

- Audio setup and calibration

They provide a controlled environment for safe equipment testing.

Coax and Connector Tools

Feedline quality is critical to station performance. Specialized tools ensure connectors are installed correctly and cables maintain proper electrical characteristics.

Common cable tools include:

- Coax strippers

- Crimping tools

- Soldering equipment

- Connector assembly tools

- Small anti-static tweezers

- Heated tweezers

Proper cable construction reduces signal loss and prevents intermittent faults.

Soldering Tools and Station Assembly

Many ham radio installations require soldered connections. Soldering irons and temperature-controlled stations allow reliable electrical joints.

Quality soldering improves:

- Signal integrity

- Mechanical strength

- Long-term reliability

Operators often use soldering tools when building antennas, repairing equipment, or assembling cables.

RF Safety and Monitoring Tools

RF exposure monitoring helps ensure safe operating conditions. Field strength meters and RF detectors measure electromagnetic energy levels near antennas and equipment.

These tools help verify compliance with safety guidelines and ensure proper station design.

Interference Detection Tools

Radio frequency interference can originate from household electronics, power systems, or nearby equipment. Specialized receivers, portable radios, and spectrum displays help locate interference sources.

Identifying interference allows operators to correct grounding issues, suppress noise sources, and restore clean reception.

Mechanical and Installation Tools

Building and maintaining antenna systems requires mechanical tools such as wrenches, torque drivers, cable cutters, and mounting hardware tools.

Proper mechanical installation improves:

- Antenna stability

- Electrical contact quality

- Weather resistance

- Long-term durability

Mechanical reliability directly affects signal performance.

Portable Field Tools

Portable operators often carry compact tool kits for setup and adjustment in remote locations. These may include small analyzers, compact multimeters, lightweight cable tools, and handheld measurement devices.

Field tools enable quick deployment and troubleshooting during portable operation.

Calibration and Accuracy

Measurement tools must provide reliable data. Periodic calibration and careful handling help maintain accuracy. Incorrect measurements can lead to improper adjustments and reduced performance.

Quality tools and proper maintenance ensure dependable results.

Choosing the Right Tools

Tool selection depends on station complexity and operating style. Basic stations require simple measurement and installation tools. Advanced stations benefit from detailed analysis and diagnostic equipment.

Operators should select tools that match their technical goals and station configuration.

Building a Practical Tool Set

Most stations benefit from a core group of tools that support everyday operation and maintenance. As stations grow more complex, additional diagnostic tools become valuable.

A well-equipped station includes tools for electrical measurement, RF analysis, mechanical assembly, and signal testing.

How Tools Improve Station Performance

Tools enable precise adjustment, reliable installation, and rapid troubleshooting. They allow operators to identify problems early and maintain consistent system performance.

By replacing guesswork with measurement, tools increase efficiency, reliability, and communication effectiveness.

Complete Guide to Ham Radio Tools

Complete Guide to Ham Radio Tools, they form the technical foundation behind every well-functioning station. They allow operators to measure performance, build reliable systems, diagnose problems, and maintain safe operating conditions. While transceivers and antennas enable communication, tools ensure those systems perform at their full potential.

Understanding and using the right tools gives operators control over their station, improves signal quality, and supports long-term reliability across all areas of amateur radio operation.

Please consider Donating to help support this channel